Other Recommendations

Viewed

TEST PRODUCTS

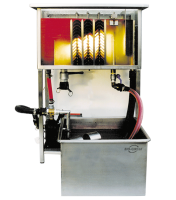

Test our products in your company.

We bring the BIO-CIRCLE brush wash table into motion - directly to you. Get a picture on the spot and see for yourself the functionality, the excellent cleaning performance and the best possible protection for the user and the environment. You also have the possibility to rent BIO-CIRCLE brush washers for 4 weeks. Test whether the BIO-CIRCLE is something for your operation.

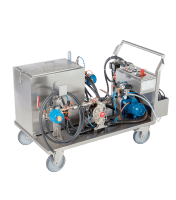

Terms and conditionsNUTZEN STATT KAUFEN

Reinigungsgeräte mieten mit Rundum-Sorglos-Service.

Mieten Sie unsere Teilereinigungssysteme im Rahmen einer Nutzungsvereinbarung und erhalten Sie umfangreiche Serviceleistungen. Unsere Geräte gibt es bereits ab einer Grundmiete von 0 Euro. Informieren Sie sich jetzt! Terms and conditions

-

-

Low application temperature, energy-saving, water-saving

-

For us, sustainability means taking responsibility

-

-

From renewable raw materials, non-flammable, VOC-free, non-marking

-

-

Suitable for the food industry, miscible with water, can be rinsed without residue

-

-

Free from / reduced volatile organic compounds according to EU regulation